NEWS

Accuracy of rolling forming machine

Publish Time:2020-09-08 15:27

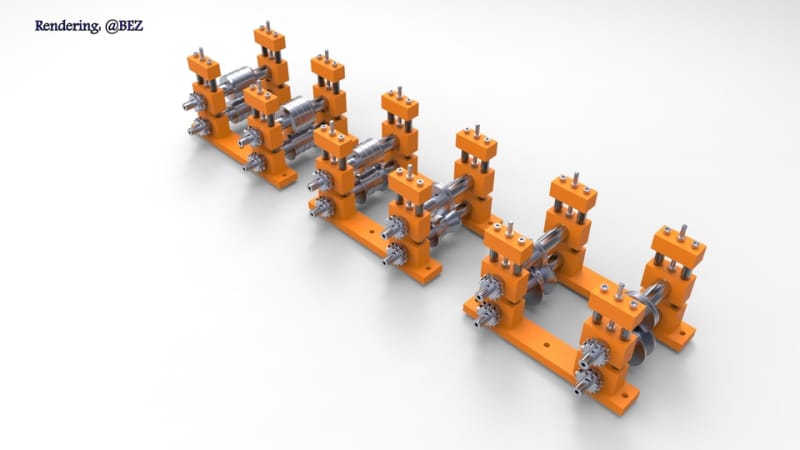

Accuracy of rolling forming machine:

1. From centimeters to millimeters, even to the road (1% mm)

2. From single accuracy to overall accuracy

3. The different precision requirements have caused our different production methods

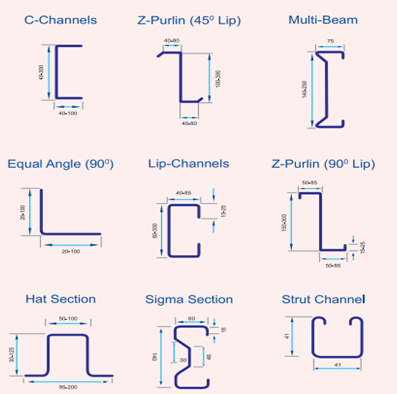

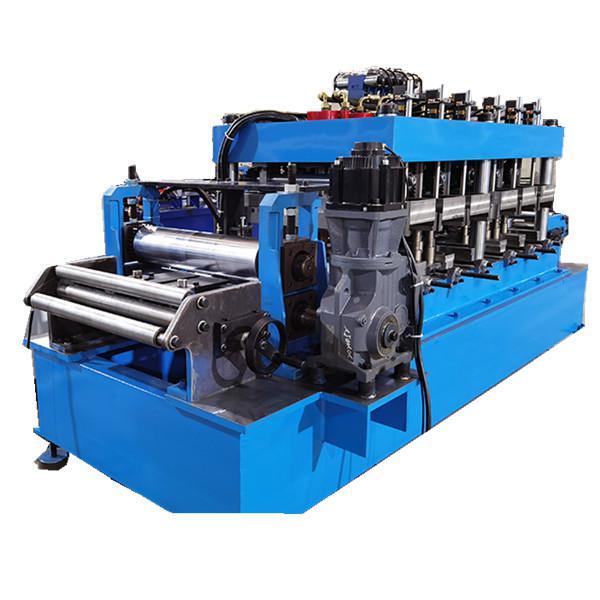

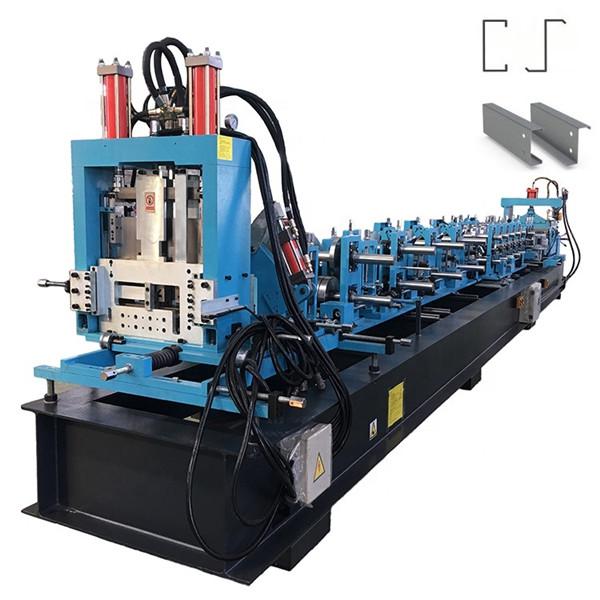

The tile press we are now producing is a profiled steel plate used as an enclosure material or floor steel plank in the construction industry in cold-formed steel. In the construction industry, the accuracy requirement is generally in centimeters, so the tile press we produce can meet the needs of our customers. When our products are not only to meet the needs of the construction industry, but also for the automobile manufacturing industry and agriculture And light industrial machinery manufacturing, shipbuilding and transportation, petrochemical power industry, instrumentation, containers, textile machinery, highways and railways, cargo containers, civil electrical appliances and daily necessities. When providing cold-formed steel products, some of these products The accuracy requirements must reach millimeters, and some accuracy requirements must even reach the level. Under such precision requirements, our products must progress from tile presses to cold-formed mechanical products, and the accuracy must be from centimeters to millimeters.

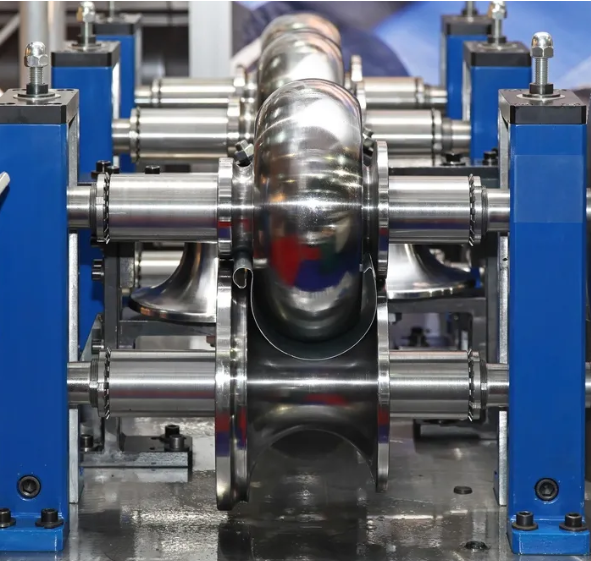

In the past when our equipment required precision, we only put forward high-standard precision requirements for the precision of the shaft and the forming wheel. However, in the production process of some products, we found that the precision requirements of the user were still not met. why? The biggest reason for this is the accumulation of errors. The simplest example: the customer’s product now requires an accuracy of less than 1mm. What is the normal production process of Anzhao, we have controlled the accuracy of the shaft and the forming wheel, but we have not The accuracy of bearing seat, wallboard, frame and other mechanical parts are not controlled, so that the error of shaft and forming wheel is controlled within 0.2mm, but the error of bearing seat is 0.2mm, and the error of wallboard is also 0.2mm. It is the blank used directly after manual welding. These errors add up to far exceed the required accuracy of 1mm. Under this circumstance, we can only rely on our manual matching for welding and matching, which may temporarily meet the product accuracy requirements, but this kind of product can only be said to be a single, unique trial product, and it cannot be performed normally. The maintenance and replacement of parts cannot be formatted for a long time, which means that it cannot be delivered to customers as qualified products. In order to achieve accuracy, to achieve a certain degree of reliability, and maintainability, all of our components must be standardized mechanical drawing and standardized mechanical processing as much as possible to improve the accuracy of all components as a whole, so as to meet the accuracy requirements of the product . When the precision of the parts is reached, its appearance is naturally standard. The mechanical equipment installed with such parts naturally meets the standard, and the natural appearance is beautiful. Therefore, the higher the precision, the more beautiful the machine.

The different precision requirements have caused our different production methods: the different precision requirements of our customers’ products have caused different quality requirements for our machinery and equipment, and the different quality requirements of our machinery and equipment have caused the level of our production costs. The fundamental difference in cost has caused the fundamental difference in our current production methods. Therefore, the accuracy requirements are directly proportional to the product quality and product price and our customer level.

Specialization, system regularization, and supporting:

There is a popular saying now: Professional people do professional things. In fact, this sentence can be understood like this: the able ones survive, the capable ones survive, and the fine ones survive. Whether a person or an enterprise, there is one truth: limited energy and limited resources. How can we devote limited energy and resources to an industry and a product that we identify, from learning to mastering, then from precise mastering to starting to study rules and regulations, this is the specialization of our enterprise. Professional products are not single and independent, so the system of natural products and the matching of products after precise control will be natural. How to specialize is actually a process of statistical induction. One is to count which kinds of cold-formed products we have, which products, which products we have made, which products we are more successful with, and which products we have product technology and production. Manufacturing basis, which products we have a dominant position in the market, or which products we have a more thorough understanding of the market, etc., make a statistical summary, and finally choose our professional products.

Recommend specialized products:

a. Heavy-duty thick plate large-scale cold-formed product production line: automobile, new steel column building material

b. Alternative products for traditional shearing and bending: air conditioning and ventilation duct integrated machine

c. Light steel keel upstream supporting products: small slitting machine, leveling and slitting machine

d. High-grade discharging, receiving, palletizing and packing lines (various shaped profiles)

e. High-speed production line (above 60m/min): unwinding-forming-tracking shear-discharging and stacking

f. Standardized tile press shear head, punching parts, feeding parts, large frame mechanical parts