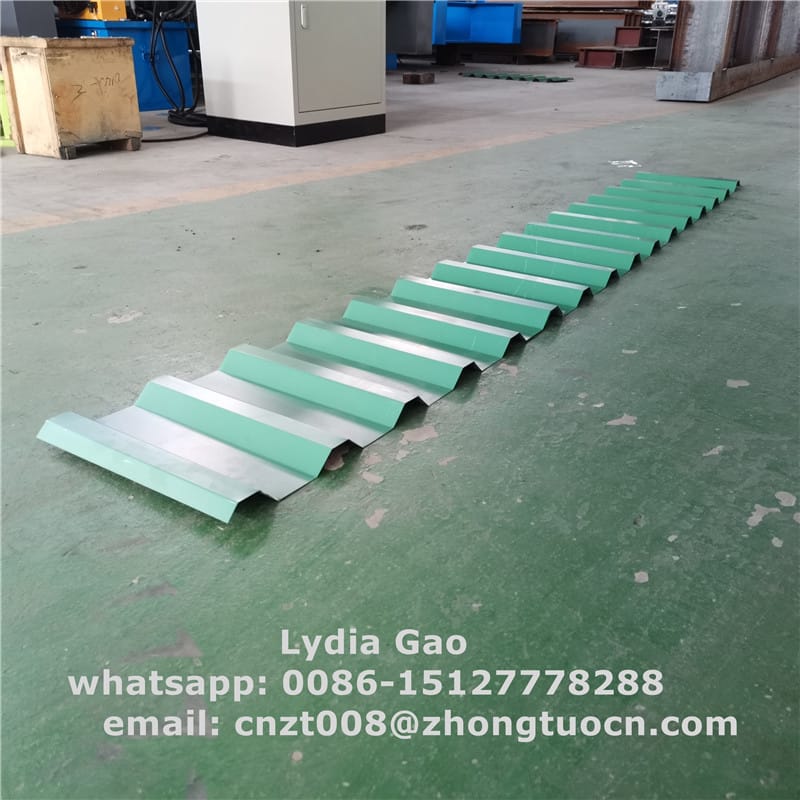

Metal roof sheet machine

R101 Trapezoidal Metal Roof Sheet Roll Forming Machine

R101 Trapezoidal Sheet Forming Machine make trapezoidal roof sheet for Mexico market.Feeding width1220mm for R101 and 914mm for R72, ( only feed different width raw material, no need to change machine)Thickness 0.3-0.7mm or gauge 23-30(to produce different thickness, no need to change machine)Yield strength:235Mpa-550MpaAny length productcan be manufacture on this roll forming machine.Main components of roll forming machine5 ton manual decoiler, forming machine with post cut, PLC controller , hydraulic station, run out tableMain features of forming machinemitsubishi or siemens control system to automatical produce with high precision21 roller stations to garantee the flat and precise of fina...

R101 Trapezoidal Sheet Forming Machine make trapezoidal roof sheet for Mexico market.

Feeding width 1220mm for R101 and 914mm for R72, ( only feed different width raw material, no need to change machine)

Thickness 0.3-0.7mm or gauge 23-30(to produce different thickness, no need to change machine)

Yield strength:235Mpa-550Mpa

Any length product can be manufacture on this roll forming machine.

Main components of roll forming machine

5 ton manual decoiler, forming machine with post cut, PLC controller , hydraulic station, run out table

Main features of forming machine

mitsubishi or siemens control system to automatical produce with high precision

21 roller stations to garantee the flat and precise of final r101 trapezoidal roof sheet

Forming machine weight about 8 tons

Easy installation

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 9000kgs |

| Size | About 11m x 1.7m x 1.5m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | PPGI and PPGL Coils |

| Thickness | 0.3-0.8mm |

| Coil width | 1220mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 22 |

| Diameter of forming rollers shafts | 80mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer’s requirement |

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line