Furring Hat Machine

Omega Hat Metal Furring Channel Making Steel Roll Forming Machine

Omega Hat Metal Furring Channel Making Steel Roll Forming MachineOmega Hat Metal Furring Channel Making Steel Roll Forming Machineis themost popular type of roll forming machines. It makes different shape of metal stud and track, which is used in the construction of various light steel keel frame, roller shutter door, industrial plants, buildings, factory, villages, warehouses, supermarkets, hotels, exhibition, shopping malls, shutter doors andect.The finished sheet usually worked for roof and wall panel . It has beautiful design,andwidely used in all over the world.We adoptexport standard technical solutionto make machine strongand stable enough.Usually it can run with the normal speed to 2...

Omega Hat Metal Furring Channel Making Steel Roll Forming Machine

Omega Hat Metal Furring Channel Making Steel Roll Forming Machine is the most popular type of roll forming machines. It makes different shape of metal stud and track, which is used in the construction of various light steel keel frame, roller shutter door, industrial plants, buildings, factory, villages, warehouses, supermarkets, hotels, exhibition, shopping malls, shutter doors and ect. The finished sheet usually worked for roof and wall panel . It has beautiful design, and widely used in all over the world.

We adopt export standard technical solution to make machine strong and stable enough.

Usually it can run with the normal speed to 25-30m/min. PLC with touch screen operation make the machine simple and easy for operation.

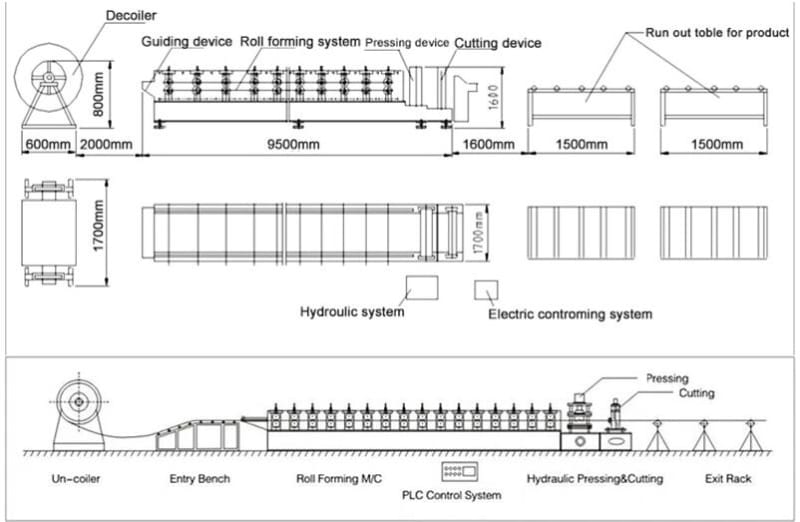

1. Production Process Diagram:

Uncoiling --- Feeding --- Roll Forming --- PLC Controlling --- Hydraulic Cutting (Punching)--- Receiving

2. Main Technical Specifications:

Name | Omega Hat Metal Furring Channel Making Steel Roll Forming Machine | |

Raw Material | Material | Aluminium PPGI PPGL GI GL |

Width | as drawing | |

Thickness | 0.3-0.6mm, customized | |

Power Required | Power | 380V 3Phase 50Hz, customized |

Main Motor | 5.5KW, Lichao, Shanghai/Siemens Brand | |

Cutting Motor | 3.0KW, Lichao, Shanghai/Siemens Brand | |

Roll Forming Machine | Support Frame | Square tube frame welded |

Forming Station | 12 rows+3 Straighting rollers, exactly according to profile drawing | |

Structure | Memorial archway | |

Shaft | 45# high grade steel, 50mm, solid | |

Roller | Cr12 | |

Transmission | Gear | |

Bearing | Standard | |

Speed | 25-30m/min | |

Electric Components | Delta / Siemens / Mitsubishi | |

Cutting Blade | Cr12Mov, quenched 58°-62° | |

Operation | Touch Screen | |

Dimension | 5.7*1.5*1.3M | |

Weight | 4.0T | |

We also provide Safety Shield, Hydraulic decoiler, Automatic stacker for your better operation. It can save labor, save cost and can guarantee your production line more safer. Above all, it can improve your work efficiency !

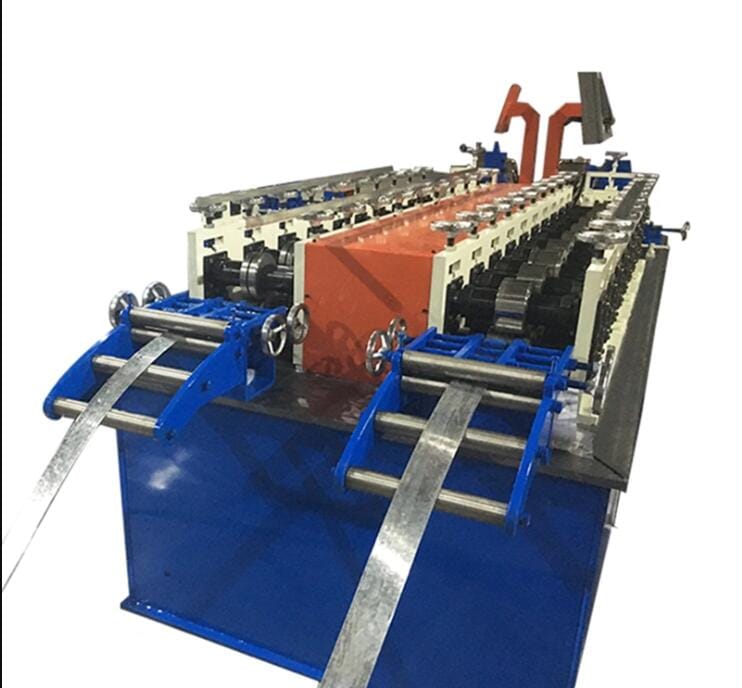

3. Pictures of Roll Forming Machine:

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line