Stud & Track Machine

USA Metal stud and track roll forming machine drywall plasterboard roll former

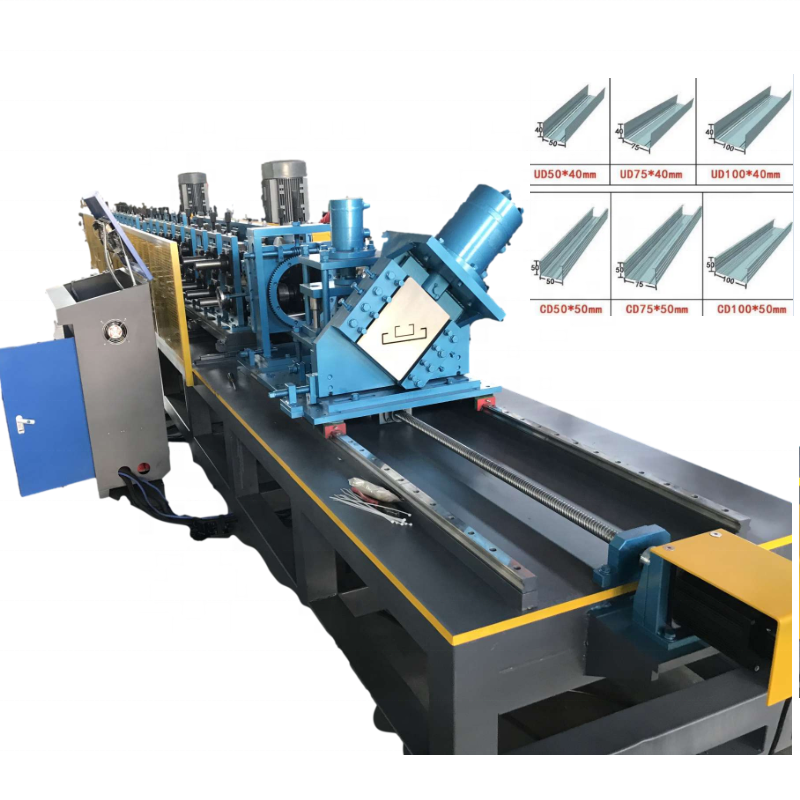

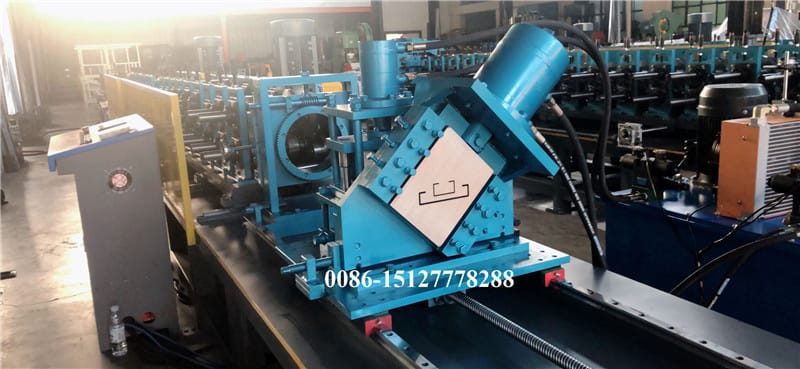

Metal stud and track roll forming machine steel drywall plasterboard roll formerStud and track roll forming machine from Cangzhou zhongtuocan be changed in 20 minutes or less to produce different width and flange heights in different gauges of material.An electro-mechanical adjustment is all that’s required to offer a wide range of stud and track widths on demand. With our stud and track roll former, you can produce studs and tracks in a wide range of material gauges and lip sizes from C stud 1 5/8 to C 6 and U track 1 5/8 to U 6as gauge and sizes requirement.Stud and Track Roll Former employs a precision flying shear to produce close tolerance parts on various widths and gauges of material...

Metal stud and track roll forming machine steel drywall plasterboard roll former

Stud and track roll forming machine from Cangzhou zhongtuo can be changed in 20 minutes or less to produce different width and flange heights in different gauges of material.

An electro-mechanical adjustment is all that’s required to offer a wide range of stud and track widths on demand. With our stud and track roll former, you can produce studs and tracks in a wide range of material gauges and lip sizes from C stud 1 5/8 to C 6 and U track 1 5/8 to U 6 as gauge and sizes requirement.

Stud and Track Roll Former employs a precision flying shear to produce close tolerance parts on various widths and gauges of materials, you can choose by spacer change or tooling change or PLC change. For the speed, there is also 45m/min, 70m/min and 100m/min for you choose. All are custom designed and offer a variety of options for your specific application.

Our Steel Studs Metal Track Drywall Framing Light Gauge Roll Forming Machine is very popular both in South America and North America market, especially in USA and Canada market. this machine can produce different sizes, and you can change the sizes automatically by operating PLC, save your time and producing cost, increase the effiency. any interest, welcome to contact us 0086-15127778288

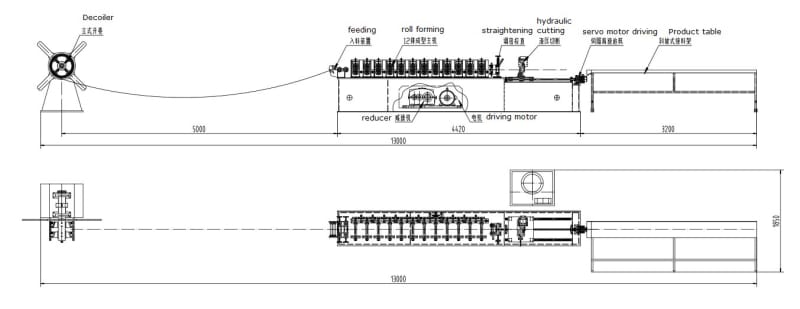

Form process of stud and track roll forming machines

No. | Name | Unit | Qty |

1 | Sheet Uncoiler | set | 1 |

2 | Roll Former | set | 1 |

3 | Die Tooling | set | 1 |

4 | In-Line Punch | set | 1 |

5 | Flying Cut-Off | set | 1 |

6 | PLC control station | set | 1 |

7 | Stacking Table | set | 1 |

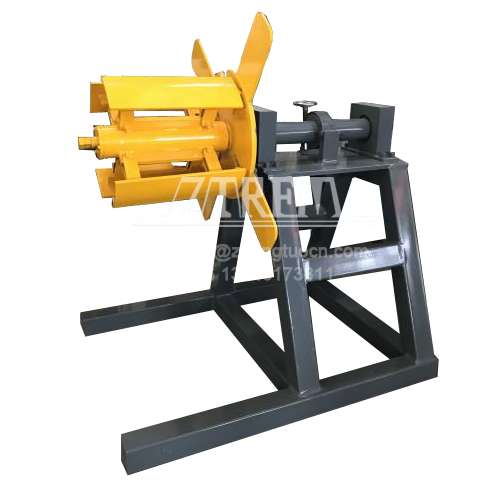

Un-coiler System

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity | Uncoiling width | Inner diameter |

1.5T | 300mm | 450-550mm |

Forming device

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,gear transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

No. | Main parameter of stud and track machine | |

1 | Length of the main part | 4800*800*1400 |

2 | Weight of main part | About 2.5 t |

3 | Voltage | 380V/50HZ3Phase (as customer's request) |

4 | Roller fixer | Guide column |

5 | Frame | Middle plate welded Memorial arch frame type |

6 | Frame thickness | 25mm |

7 | Drive mode | Gear |

8 | Material of rollers | GCr12MoV quenching treatment58-60° |

9 | Material of shafts | 45# steel with tempering |

10 | Diameter of shafts | φ40mm |

11 | Number of rollers | 12 rollers |

14 | Main power | 4kw (Cycloidal planetary gear speed reducer) |

15 | embossing and Logo is acceptable | |

Cutting device

Advanced hydraulic drive, automatic punching and cutting after forming, no distorting or wasting, high level safety factor.

Blade Material | Cutting system |

GCr12MoV quenching treatment58-60° | Full automatic |

Controlling device

Screen | PLC | Coder |

Text screen displayer |

Taida DVP14ES from Taiwan |

Omron |

Hydraulic

Orgin | Power |

Advanced hydraulic system from Taiwan | 3kw |

Except this metal stud and track roll former, we also have other machines for you choose, welcome to contact us for custom request.

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line