Struct Channel Machine

SHAFT WALL PROFILE CASSETTE SYSTEM ROLL FORMING MACHINE

SHAFT WALL PROFILE CASSETTE SYSTEM ROLL FORMING MACHINE ACassette system roll forming machinehas beendesigned to produce various cold formed section channels by quick changing different cassettes that share a common machine base.A cassette systemroll forming machine shall have several sets of individual cassettes which consists of different rolling tools, shafts, and forming stands. Like a conventional roll former, a cassette roll forming machine also consists of de-coiler, roll former, transmission system, hydraulic system, sometimes cooling system, cut-off tooling, and control system, but the biggest difference is the roll former.The roll former in a conventional roll forming machine has r...

SHAFT WALL PROFILE CASSETTE SYSTEM ROLL FORMING MACHINE

A Cassette system roll forming machine has been designed to produce various cold formed section channels by quick changing different cassettes that share a common machine base.

A cassette system roll forming machine shall have several sets of individual cassettes which consists of different rolling tools, shafts, and forming stands. Like a conventional roll former, a cassette roll forming machine also consists of de-coiler, roll former, transmission system, hydraulic system, sometimes cooling system, cut-off tooling, and control system, but the biggest difference is the roll former.

The roll former in a conventional roll forming machine has rolling tools with shafts mounted on the roll forming stands and the forming stands are welded or fixed with screws to the machine base; while the roll former in a cassette roll forming machine is composed of two main parts: Main Roll forming Base, and Rolling Tools. There is only one roll forming base, but the rolling tools are divided into a few sections (2-4 sections) and each section consists of six to eight rolling tools with shafts mounted on the roll forming stands which are welded or fixed by screws to a subsidiary machine base, the subsidiary base is normally made of metal plate, c channels, h beam, or square tubes etc, and we call these sections with rolling tools and shafts mounted on the subsidiary bases Cassettes.

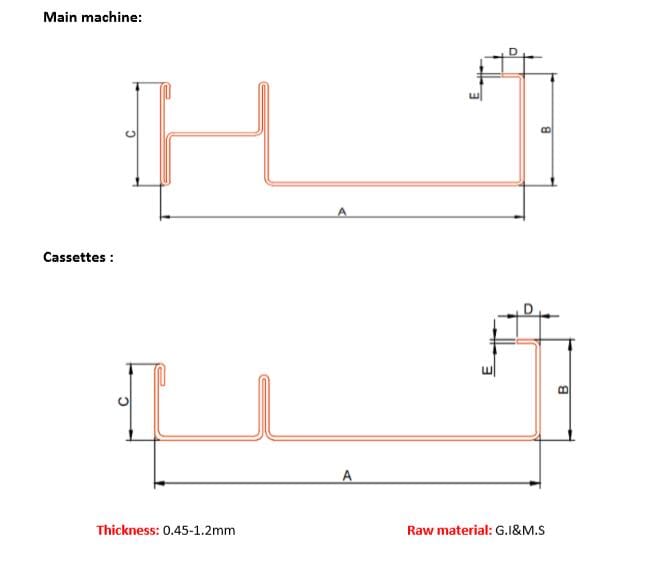

The drawing profile:

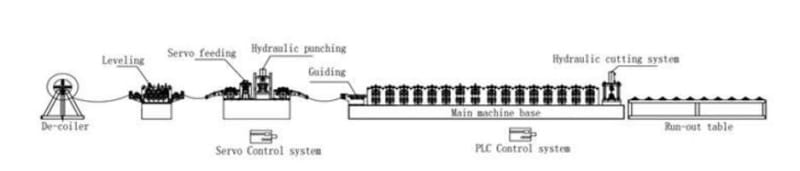

The work flow of the casstte system roll forming machine:

De-coiler----Electric leveling machine----Servo feeding system----Hydraulic punching system----Roll forming machine-----Servo Flying Hydraulic cutting------Run-out table

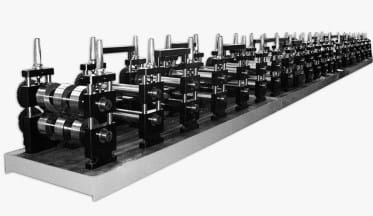

Based on the customer requirements and our experience, we design the casstte system Roll Forming Machine like following picture:

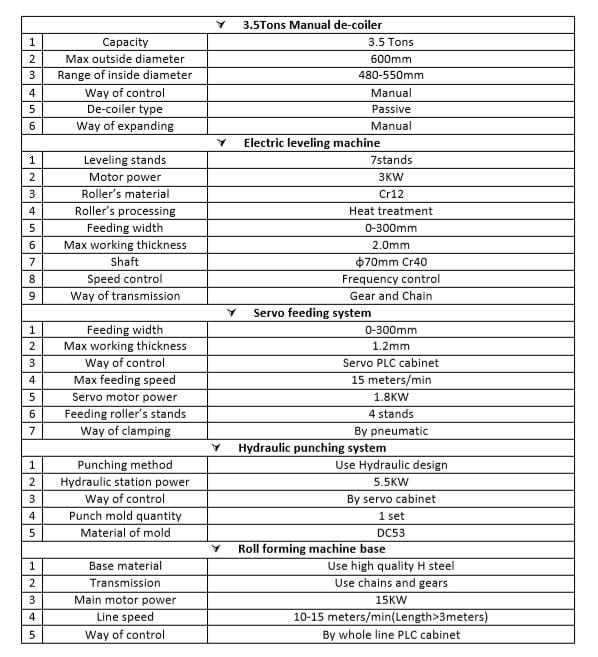

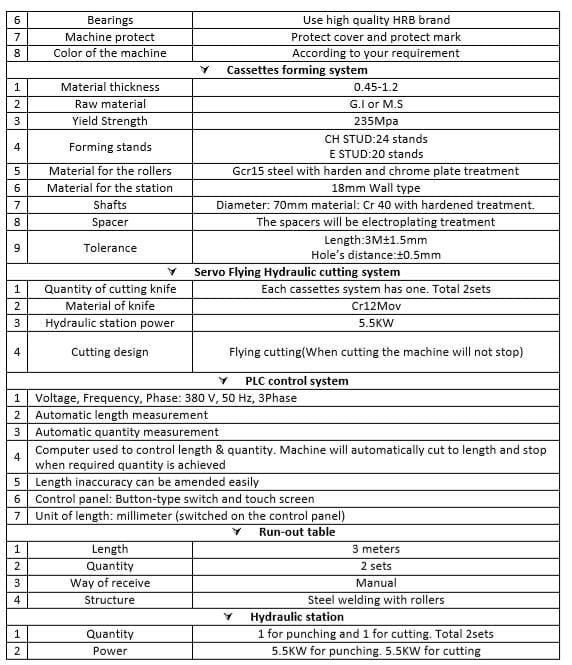

The composition of the whole line and Technical parameters

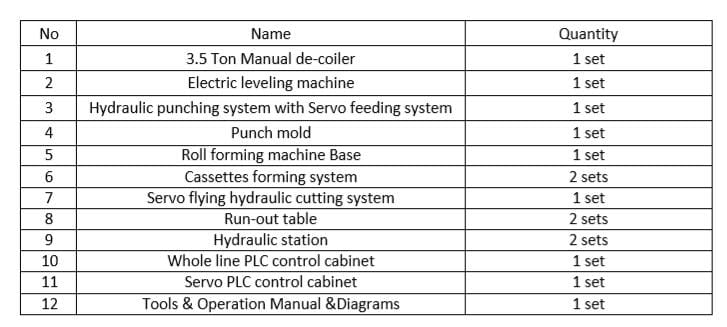

Packing list

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line