Metal roof sheet machine

High Speed Corrugated Metal Roofing Sheet Roll Forming Machine for Residential & Commercial

High Speed Corrugated Metal Roofing Sheet Roll Forming Machine for Residential & CommercialAmerican Roofing and Sheet Metal Roll Forming MachineCorrugated Metalsroofing and siding products are the standard patterns for the industry. They provide improved strength in the materials and are easy to install and economical to use. The most common uses are industrial, commercial and architectural applications. These products offer a rib pattern of 2.67” centers and a depth of ½”, ¾”, or 7/8”.Because of its shape, corrugated roofing is extremely durable. Because the screws for fastening penetrate through the peak of the ribs, these sheets require support strips to stabilize the material. The ...

High Speed Corrugated Metal Roofing Sheet Roll Forming Machine for Residential & Commercial

American Roofing and Sheet Metal Roll Forming Machine

Corrugated Metals roofing and siding products are the standard patterns for the industry. They provide improved strength in the materials and are easy to install and economical to use. The most common uses are industrial, commercial and architectural applications. These products offer a rib pattern of 2.67” centers and a depth of ½”, ¾”, or 7/8”.

Because of its shape, corrugated roofing is extremely durable. Because the screws for fastening penetrate through the peak of the ribs, these sheets require support strips to stabilize the material. The ribs and valleys’ curvature inhibits the screws from properly sealing in the valleys.

The advantage of high speed corrugated roof panel machine is as bellow:

Gear box transmission, more stable when machine run in high speed.

Fly shearing device, non-stop cut, make the machine run in very high speed.

High quality Cr15 rollers, make the machine run in long service life.

Please check the feedback from our American customer:

Top Quality And Cheap Sheet Corrugated Roof Panel Roll Forming Machine | ||

1.Formed Material | PPGI,GI,AI,GL | Thickness:0.3-0.8mm Width:1000mm/1250mm(As per profile drawing) |

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

3.Main body | Roller station | 16 rows(As your requirement) |

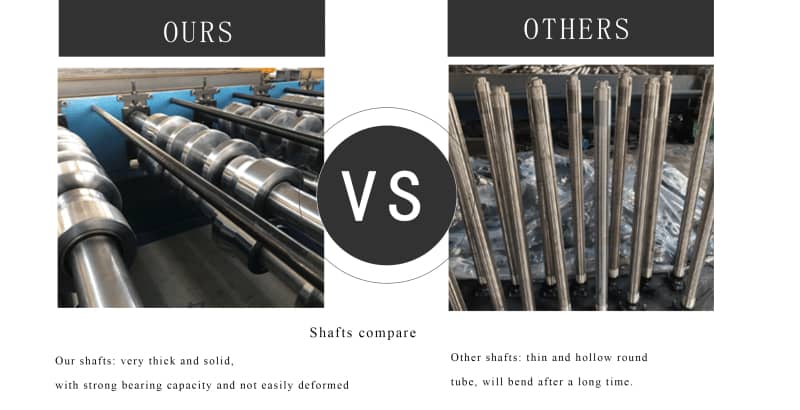

Diameter of shaft | 80mm solid shaft | |

Material of rollers | 45# steel, hard chrome plated on the surface | |

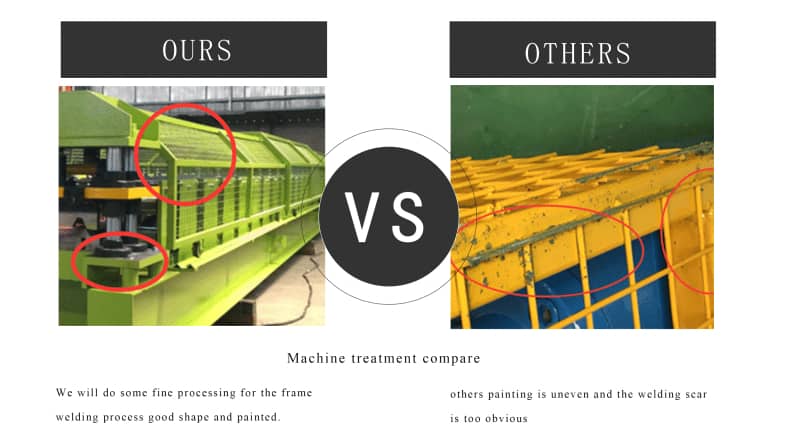

Machine body frame | 350 H steel | |

Drive | Chain transmission | |

Dimension(L*W*H) | 7500*1600*1600(customize) | |

Weight | 5.5T | |

4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

5.Power | Motor Power | 5.5KW |

Hydraulic system power | 4KW | |

6.Voltage | 380V 50Hz 3Phase | As your requirement |

7.Control system | Electric Box | Customized(famous brand) |

Language | English(Support multiple languages) | |

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

8.Forming Speed | 15-20m/min | The speed is adjustable as customer's request |

Please check our details

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line