Metal roof sheet machine

Anti condensation felt condenser Stop Dripstop metal roof sheet roll forming machine

Anti condensation felt condenser Stop Dripstop metal roof sheet roll forming machineDripstop anti-condensation felt membrane can be applied to the reverse ofCladco Steel Roofing Sheets, to 34/1000 Box Profile, 32/1000 Box Profile, 13/3 Corrugated and 41/1000 Tile Form panels.As moisture condenses in high temperature and humidity conditions, Dripstop controls how cyclical condensate forms onto the underside of steel roofing. It does not prevent condensation from forming and, when working correctly, feels damp to the touch.HOW TO STOP CONDENSATION ON STEEL ROOFING SHEETSCangzhou zhongtuo roll forming machine can help you solve the problem.Please check the finished Anti condensation felt conden...

Anti condensation felt condenser Stop Dripstop metal roof sheet roll forming machine

Dripstop anti-condensation felt membrane can be applied to the reverse of Cladco Steel Roofing Sheets, to 34/1000 Box Profile, 32/1000 Box Profile, 13/3 Corrugated and 41/1000 Tile Form panels.

As moisture condenses in high temperature and humidity conditions, Dripstop controls how cyclical condensate forms onto the underside of steel roofing. It does not prevent condensation from forming and, when working correctly, feels damp to the touch.

HOW TO STOP CONDENSATION ON STEEL ROOFING SHEETS

Cangzhou zhongtuo roll forming machine can help you solve the problem.

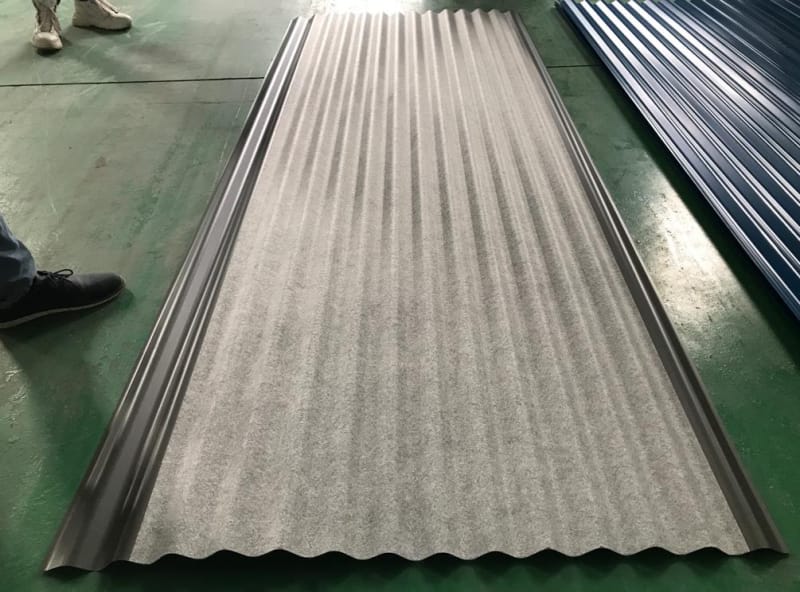

Please check the finished Anti condensation felt condenser Stop Dripstop metal roof sheet from our machines.

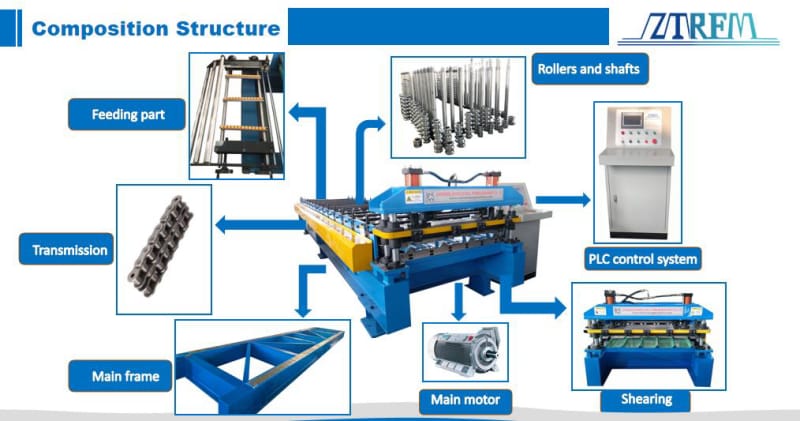

Double layer Anti condensation felt condenser Stop Dripstop metal roof sheet roll forming machine | ||

1.Formed Material | PPGI,GI,AI | Thickness:0.3-0.8mm Width:1000mm/1250mm(customized) |

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

3.Main body | Roller station | 20+22 rows(As your requirement) |

Diameter of shaft | 80mm solid shaft | |

Material of rollers | 45# steel, hard chrome plated on the surface | |

Machine body frame | 350 H steel | |

Drive | Chain transmission | |

Dimension(L*W*H) | 9500*1600*1600(customize) | |

Weight | 11T | |

4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

5.Power | Motor Power | 7.5KW |

Hydraulic system power | 5.5KW | |

6.Voltage | 380V 50Hz 3Phase | As your requirement |

7.Control system | Electric Box | Customized(famous brand) |

Language | English(Support multiple languages) | |

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

18.Forming Speed | 15-20m/min | The speed is adjustable |

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line