Metal roof sheet machine

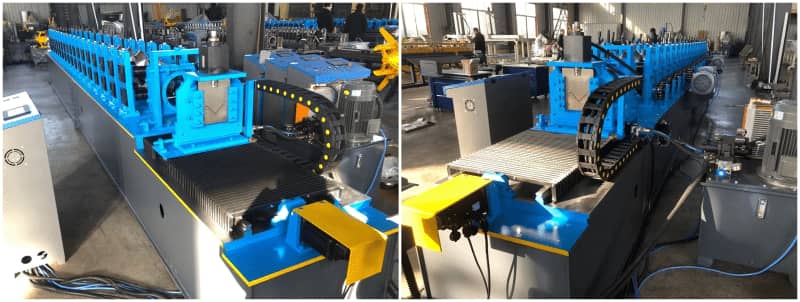

Drip Edge Profiles Roll Forming Machine FHA Flashing Roll Former Manufacturer

Drip Edge Flashing is designed to control the direction of running water and help protect the underlying building components, such as facia. It is installed around the entire perimeter of the roof, this mainly serves as a watertight seal. If installed properly, only the face of the metal is exposed with the shingles covering the top side of the metal flashing. It is recommended to overlap your drip edge seams to prevent water infiltration. This is typically an overlap of just 3 to 6 inches.Drip Edge Flashing is made with heavy duty, 28 gauge, galvanized steel. It features an outward projecting lower edge (drip edge). It is available in multiple deck and face measurements, along with five col...

Drip Edge Flashing is designed to control the direction of running water and help protect the underlying building components, such as facia. It is installed around the entire perimeter of the roof, this mainly serves as a watertight seal. If installed properly, only the face of the metal is exposed with the shingles covering the top side of the metal flashing. It is recommended to overlap your drip edge seams to prevent water infiltration. This is typically an overlap of just 3 to 6 inches.

Drip Edge Flashing is made with heavy duty, 28 gauge, galvanized steel. It features an outward projecting lower edge (drip edge). It is available in multiple deck and face measurements, along with five color options. This product is sold in 5′ pieces, and is also available in 10′ long pieces.

Cangzhou zhongtuo roll forming machine company has produced lots of Drip Edge Flashing Machines and exported to American, especially Florida market and also got many positive feedbacks from our clients, such as F8 drip edge, F5 drip edge, Gutter Apron, Asphalt drip edge, Gravel stop, T style drip edge and so on.

Technical parameter:

Decoiler:

Loading capacity | 1.5 Tons |

Uncoiling width | 300 mm |

Inner diameter | 450-550 mm |

Structure | Iron plate welded structure |

Main roll forming machine:

Voltage | 380V-3P-50HZ (Or as your request) |

Drive mode | Chains drive |

Material of roller | GCr12 Mov |

Material of shaft | 45# steel with tempering |

Shaft diameter | Φ 50 mm |

Numbers of roller | 14 roller stations |

Main motor power | 5.5+5.5 KW |

Roll forming speed | 0-45 m/min |

Cutting system:

Cutter material | Cr12 |

Power supply | Hydraulic power with tracking cutting |

Cutting power | 5.5 KW |

Receiving table:

Quantity | 1 set |

Length | 3 m |

Motor power | 0.75 KW |

Hydraulic oil pump station:

Hydraulic motor power | 3 KW |

Hydraulic oil | 46# hydraulic oil |

Cooling system | With cooling fan on it |

PLC control system:

Language | English/Chinese or as your reuqest |

Voltage | 380V-3P-50HZ or as your request |

Length control | Yes |

Speed control | Yes |

Operating panel | Have buttons and touch screen |

PLC brand | DELTA brand |

Low voltage electrical apparatus | Schneider brand |

Counter | Omron brand |

Our machine frame use vertical iron casting frame to ensure stable running, and use chains driving.. It will have protective cover box on it.

The roller use Cr 12 material, this kind of material hardness is more higher than other kind of material, then can provide more longer service life. The rollers have heat treatment, chromed treatment, quenched treatment to ensure it's quality.

For the cutting device, we adopt tracking cutting to imporve the cutting speed, the machne speed max can reach to 40 m/min.

About the product collect tablel and packing device, we adopt automatic type. The product collect table can transfer the product automatically to packing table.

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line