C & Z Purline Machine

The C/U/Z purlin roll forming machine adjustable

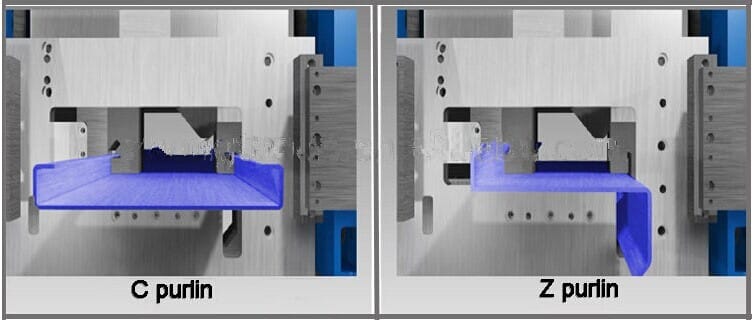

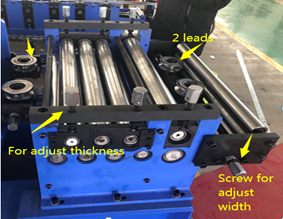

The C/U/Z purlin roll forming machine adjustableC Z purlin cold roll forming machine is a machine can produce many sizes,Generally,there are three types of machine, c purlin machine, z purlin roll forming machine, C Z Section Steel Purlin Machine. The Web width can be 60-300mm Flange height can be 30-80mm, it is adjustable from min to max. The size of holes can be design by customers.The drawing profiles for your referenceComponentsofproductionline:NO.NameUnitQty1.5 Tons Manual Decoilerset12.Main forming machineLeveling Guiding Feeding deviceset1Forming deviceset1Automatic shearing part(Post cutting two pillar type)set13.PLC control systemset14.Hydraulic oil pump stationset15.Receiving table...

The C/U/Z purlin roll forming machine adjustable

C Z purlin cold roll forming machine is a machine can produce many sizes,Generally,there are three types of machine, c purlin machine, z purlin roll forming machine, C Z Section Steel Purlin Machine. The Web width can be 60-300mm Flange height can be 30-80mm, it is adjustable from min to max. The size of holes can be design by customers.

The drawing profiles for your reference

Components of production line:

NO. | Name | Unit | Qty |

1. | 5 Tons Manual Decoiler | set | 1 |

2. Main forming machine

| Leveling Guiding Feeding device | set | 1 |

Forming device | set | 1 | |

Automatic shearing part (Post cutting two pillar type) | set | 1 | |

3. | PLC control system | set | 1 |

4. | Hydraulic oil pump station | set | 1 |

5. | Receiving table | set | 1 |

Main roll forming machine parameters:

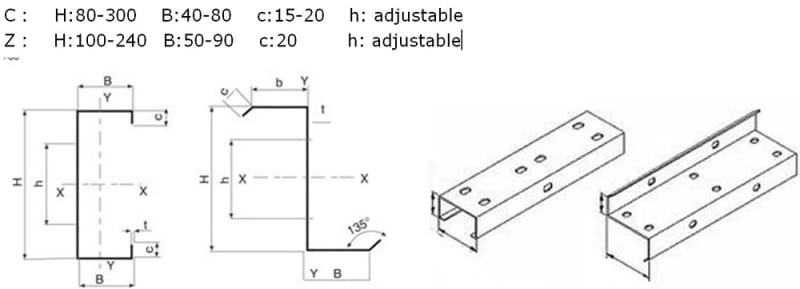

Leveling: 7 rollers:top three,down four (For confirm the coil be neat and smooth) |

Roller material:45# steel,chromed and quenched (The material of rollers could stop scratching the zinc of the steel.) |

Guiding device:With 2 leads before the leveling device and 2 leads after. (For confirm the feeding position right for roll forming) |

Width: adjustable(With the screws) |

Thickness:adjustable(With the screws) |

1. Machine frame:Weld structure. | |

2. Rollers:18 sets,after chromed and quenched.For long time using with anti-wear. | |

3. Roller Material:Main rollers:GCr15 Supporting side rollers:Cr12 high frequency heat treatment HRC50-55 ℃,accurate grinding, surface polished,hard chrome | |

4. Shafts Material:Motor drive shaft: 40Cr steel Other roll shaft: 45# steel Roller Processing technology: rough moulding Processing technology: quenching and tempering treatment HB210-230,rough car and cylindrical grinding,polishing surface hard chrome plating | |

5. Motor power: 18.5 KW | |

6. Forming speed: 0-30 m/min | |

7. Transmission way: By chain | |

8.With the protect cover | |

Size change | Unbridled shearing system, you can cut all size products by adjusting the blade,it is much easier than traditional shearing system. |

Cutting method | Hydraulic cutting with two hydraulic cylinders Give strong power for cutting |

Cutting system | Full Automatic Cutting |

Cutter material | GCR12 chromed and quenched Anti-wear.For long times using. |

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line