Stud & Track Machine

Stud and track machine CU 50-150 profile making machine

Stud and track machineCU 50-150 profilemaking machine with punchingFor the combinedGalvanized Steel Metal Stud and Track Roll Forming Machine, it is designed for House Building, we have two types: one is made by adjusting spacer and the other we make two separated machines by different shaft and rollers. When you want to save machine cost, please choose the first option. When you need to do huge production, please choose the second optionsStud and track machineCU 50-150 profilemaking machine; In the following part, I will introduce the second types:The machine of Stud and track machineCU 50-150 profilemaking machine allows you to make the sizes from 50 to 150 width range adjustment by the PL...

Stud and track machine CU 50-150 profile making machine with punching

For the combined Galvanized Steel Metal Stud and Track Roll Forming Machine, it is designed for House Building, we have two types: one is made by adjusting spacer and the other we make two separated machines by different shaft and rollers. When you want to save machine cost, please choose the first option. When you need to do huge production, please choose the second options Stud and track machine CU 50-150 profile making machine; In the following part, I will introduce the second types:

The machine of Stud and track machine CU 50-150 profile making machine allows you to make the sizes from 50 to 150 width range adjustment by the PLC. The punching is also adjustable by PLC. The machine working speed can reach 45 meter per minutes. Here is the Stud and track machine CU 50-150 profile making machine for your reference:

The advantages of Stud and Track Roll Forming Machine with size-quick- change type are as follows:

1. Produce different purlin size without changing rollers or spacers.

2. No need changing cutter for different size.

3. Easy operation, low maintenance cost

4. Infinite sizing (any size within machine range),help to save material

5. Optional Punch hole at any position of purlin web side and flange side

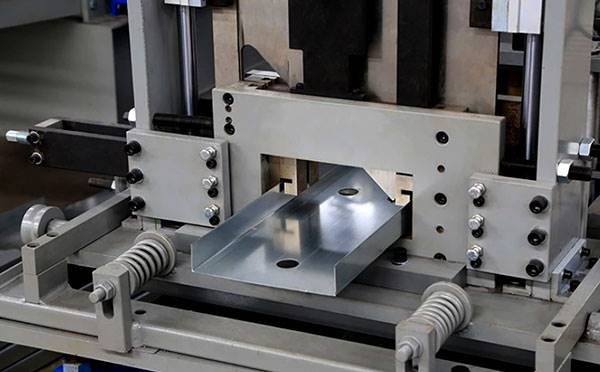

CU stud and track machine post cutter

No need to change cutter for different size, made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 30mm steel plate by welding

Pre-punching & Pre-cutting, stop to punch, stop to cut hydraulic motor:4KW, Hydraulic pressure range: 0-16Mpa

Other details of Stud and Track Roll Forming Machine for CU50-150 profile

Suitable for material with thickness 0.8-2.0mm

Shafts manufactured from 45#,

Main shaft diameter=φ70mm, precision machined

Motor driving, Gear chain transmission, about 18 rollers to form.

Main motor=7.5KW, Frequency speed control. Forming speed approx.18m/min

PLC Control System (Touch screen

Just adjust required WEB, HEIGHT and LIP by hand wheel with the help of

Position clock (with digit display for easy operation) on it,

And then input the required production data on the touch screen.

For those machines, if you want to know more information, please contact us at any time.

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line