Stud & Track Machine

Resilient Furring Channel Making Machine Metal Channels Z Furring Drywall Channels Roll Forming Machine

Resilient Furring Channel Making Machine Metal Channels Z Furring Drywall Channels Roll Forming MachineWhat is resilient channel used for?Resilient channels are low cost methods ofreducing sound transmission between walls and ceilings. As sound waves travel through the walls and ceilings, the sound waves are dampened because they create an extra distance between the wall and the insulation. It is widely used in American market and Canada market.Resilient channel provides a ½” offset between gypsum board and wall studs or ceiling rafters, enhancing acoustical performance and achieving higher STC ratings in wall and floor-ceiling assemblies. RC1 and RC2 have 1 ¼” attachment flanges, while...

Resilient Furring Channel Making Machine Metal Channels Z Furring Drywall Channels Roll Forming Machine

What is resilient channel used for?

Resilient channels are low cost methods of reducing sound transmission between walls and ceilings. As sound waves travel through the walls and ceilings, the sound waves are dampened because they create an extra distance between the wall and the insulation. It is widely used in American market and Canada market.

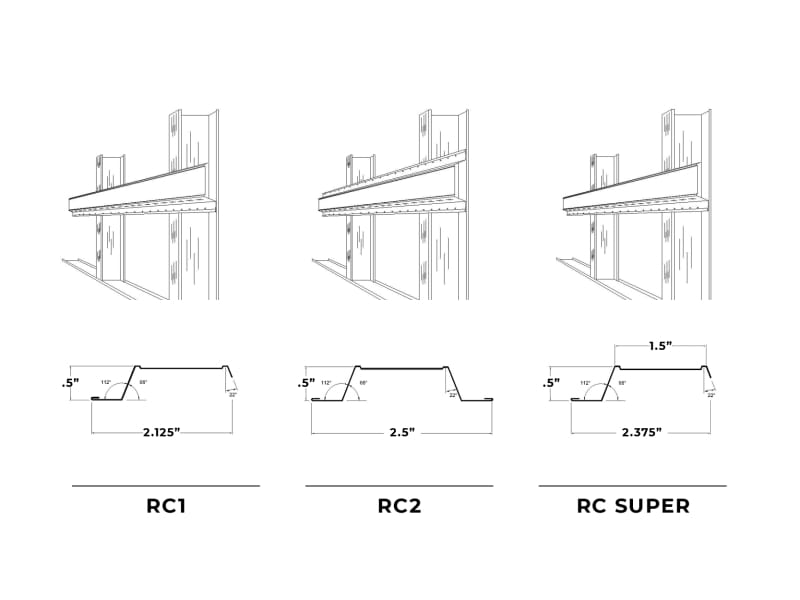

Resilient channel provides a ½” offset between gypsum board and wall studs or ceiling rafters, enhancing acoustical performance and achieving higher STC ratings in wall and floor-ceiling assemblies. RC1 and RC2 have 1 ¼” attachment flanges, while RC Super has a 1 ½” flange.

RC-1 Single Leg Resilient Channel

Super Stud RC-1 will enhance the STC rating of your metal or wood framing project. Used as a cross-furring member, RC-1 is installed perpendicular to the framing members. Pre-punched for easy attachment with holes 2” O.C. Screws should be used to attach RC -1 to metal or wood framing as nailing is not recommended.

RC-2 Double Leg Resilient Channel

Super Stud RC-2 is typically used for ceiling applications with multiple layers of gypsum board. It also enhances the STC rating of your metal or wood framing project. Used as a cross-furring member, RC-2 is installed perpendicular to the framing members. Pre-punched for easy attachment with holes 2” O.C. Screws should be used to attach RC -2 to metal or wood framing as nailing is not recommended.

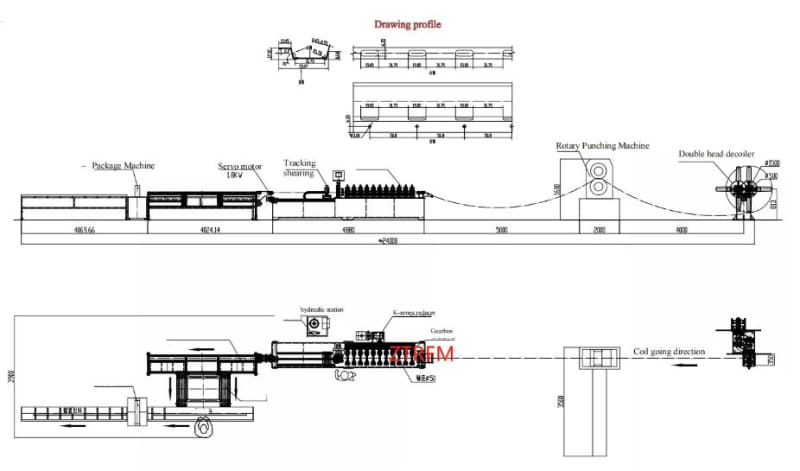

Features of Half Hat Furring Resilient Channel rolling forming machine:

1. The highest speed it can reach 70m/min including the punching process.

2. Design with double head decoiler for changing coil easily and supporting working in a high speed.

3. Use the rotary punching instead of normal CNC punching, small noise but higher speed.

4. 16 roller station rolling forming machine with servo tracking system.

5. With the package machine for fast package.

6. Whole line is fully automatic, normally speaking one worker can make the work easily.

7. PLC operation.

(1/2" HEIGHT)Resilient Channel rolling forming machine | ||

1.Formed Material | GI | Thickness: 0.3-1.0mm |

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

3.Main body | Roller station | 14 rows(As your requirement) |

Diameter of shaft | 50mm solid shaft | |

Material of rollers | 45# steel, hard chrome plated on the surface | |

Machine body frame | Metal steel welded | |

Drive | Gearbox transmission | |

Dimension(L*W*H) | 5500*800*1200(customize) | |

Weight | About 3T | |

4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

5.Power | Motor Power | 7.5KW |

Hydraulic system power | 5.5KW | |

6.Voltage | 380V 50Hz 3Phase | As your requirement |

7.Control system | Electric Box | Customized(famous brand) |

Language | English(Support multiple languages) | |

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

18.Forming Speed | 70m/min(customized) | Speed is adjustable according to customer's request |

Layout of Half Hat Furring Resilient Channel rolling forming machine:

Working video of Half Hat Furring Resilient Channel rolling forming machine:

https://www.youtube.com/watch?v=QWzx5E6nKus&t=3s

https://www.youtube.com/watch?v=EiwKHhucYLs&t=20s

Other roll formers for you choose:

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line