Stud & Track Machine

Light Gauge Stud & Track Machine Structural Stud and Track Roll Forming Machine

Heavy Gauge Galvanized Steel Metal Stud& Track Machine Drywall Stud Roll Former Steel Framing RollformerHeavy gauge metal studs and tracks are used in load bearing walls and structural applications such as exterior walls. Light gauge metal studs are used in non-load bearing applications such as some interior walls, half-walls, and partitions.Cangzhou zhongtuo roll forming machine company can produce all kinds of fully automatic studs and tracks roll formers from low speed to high speed. You can tell us your budget and what sizes of studs and tracks you want to produce, then we give you some advice.Popular drawing in US and Canada for your reference:Automatic stud and track rolling forming ma...

Heavy Gauge Galvanized Steel Metal Stud & Track Machine Drywall Stud Roll Former Steel Framing Rollformer

Heavy gauge metal studs and tracks are used in load bearing walls and structural applications such as exterior walls. Light gauge metal studs are used in non-load bearing applications such as some interior walls, half-walls, and partitions.

Cangzhou zhongtuo roll forming machine company can produce all kinds of fully automatic studs and tracks roll formers from low speed to high speed. You can tell us your budget and what sizes of studs and tracks you want to produce, then we give you some advice.

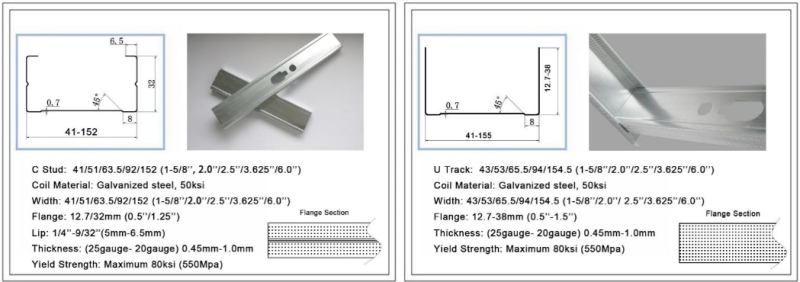

Popular drawing in US and Canada for your reference:

Automatic stud and track rolling forming machine design:

Material Coil - Decoiling - Roll Forming (- Flying Punching) - Flying Cutting Off - Finished Profile.

NO. | Equipment | Specification | Qty. |

1 | Manual Decoiler | (1) Inner Diameter: Ø 460 - 510 MM (2) Loading Capacity: 1000 KGS (3) Manual Operating Type: Manual Expansion To Tighten The Coil | 1 Unit |

2 | Roll Forming Machine | (1) Quantity Of Rollers: 12 Groups (2) Roller’s Material: Cr12 Steel, Heat Treatment, Quenched (3) Roller’s Surface Treatment: Polished (4) Roller’s Main Shaft: Ø 40 MM, 40 Cr Steel, Quenched & Heat Treatment (5) Bearing: HRB Bearing, Best In China (6) Machine Side Wall: 25 MM (7) Machine Base: Welded By 80 Square Pipe (8) Driving Method: Chain & Gear Or Gearbox (9) Coolant System: Equipped | 1 Unit |

3 | Flying Cut-Off Device | (1) Hydraulic Pump Stand: 1 Set, Auto Start / Stop (2) Hydraulic Cut Modular: 1 Set (3) Modular Material: Cr12Mov (CN Standard) / SKD11 (JP Standard) (4) Length Tolerance: ± 1.0 MM (5) TBI Linear Guideway & Ball Screws: 1 Set (6) Hydraulic Components: Taiwanese (7) Hydraulic Overload Protection Setting: Maxi. & Mini. Pressure, Pump Stand & Forming Machine Stops & Starts, With Wind Coolant System, Filter Function | 1 Unit |

4 | Run-Out Table | / | 1 Set |

5 | Control System | (1) Controller: Motion Tracing Controller, Single Axis (2) Touchable Screen: 7” Color Screen, WEINVIEW (3) Encoder: Omron, Japanese (4) Button / Knob: Schneider, France (5) Speed Control: Frequency Converter (6) Power Supplier: 380 V, 50 HZ, 3 Phs; Customized | 1 Set |

For the punching part:Normally speaking, the high speed stud and tack rolling forming machine speed will be delayed by the punching system. Different with others, we use the non-stop punching, by this way, no matter how many types you want to punch, we still can reach the speed of 70 to 120 meter per minute.

When the machine working in high speed, the workers are hard to do the collection of the stud and track. Then you can choose the automatic package system, it can help you package the profiles orderly and then package them well for loading.

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line