Furring Hat Machine

Top Hat Channel / Furring Channel Roof Panel Roll Forming Machine

Top Hat Channel / Furring Channel Roof Panel Roll Forming Machine Main specification1.Material: GI, Carbon steel2.Material thickness: 1.5-3.0mm3.Main power: 15KW4.Machine diameter: about 11500x1500x1300mm ( LXWXH )5.Weight of machine: about 10 Ton6.Main Technical Specification:7.Decoiler: Manual or hydraulic decoiler ( customer can choose )8.Weight capacity of decoiler: 5 Ton9.Forming station: 1810.Principle axis: 75mm diameter11.Forming speed: 0-15m/min12.Drive type: 1.5' chain transmission13.Roller material: GCr15 steel, quenched and heated process14.Main power: 15KW15.Hydraulic power: 7.5KW16.Electrical Control: PLC Frequency Control System with touch screen17.PLC: PANASONIC Brand...

Top Hat Channel / Furring Channel Roof Panel Roll Forming Machine

Main specification

1. Material: GI, Carbon steel

2. Material thickness: 1.5-3.0mm

3. Main power: 15KW

4. Machine diameter: about 11500x1500x1300mm ( LXWXH )

5. Weight of machine: about 10 Ton

6. Main Technical Specification:

7. Decoiler: Manual or hydraulic decoiler ( customer can choose )

8. Weight capacity of decoiler: 5 Ton

9. Forming station: 18

10. Principle axis: 75mm diameter

11. Forming speed: 0-15m/min

12. Drive type: 1.5' chain transmission

13. Roller material: GCr15 steel, quenched and heated process

14. Main power: 15KW

15. Hydraulic power: 7.5KW

16. Electrical Control: PLC Frequency Control System with touch screen

17. PLC: PANASONIC Brand

18. Encoder: OMRON Brand

19. Transducer: PANASONIC Brand

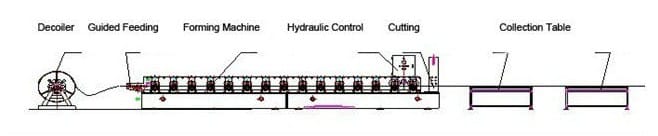

Main components

1. Decoiler ----------------------------------------------- 1 Unit

2. Feeding & Leveling -------------------------------- 1 Unit

3. Main roll forming machine ------------------------ 1 Unit

4. Hydraulic cutting device --------------------------- 1 Unit

5. Hydraulic Station ------------------------------------ 1 Unit

6. PLC computer control ------------------------------ 1 Unit

7. Output table ------------------------------------------- 1 Unit

working flow

Decoiler --- Fedding & Leveling --- Roll Forming --- Cut-to-length --- Run out table

Application

Metal angle, steel angle, angle steel, l section, wall angle, l shape, l profile

Competitive Advantages

Best Design Oriented for Your Special Requirements

High Quality

Reasonable Price

Good after Service

1 Year Warranty

More Than 10 Years Experience

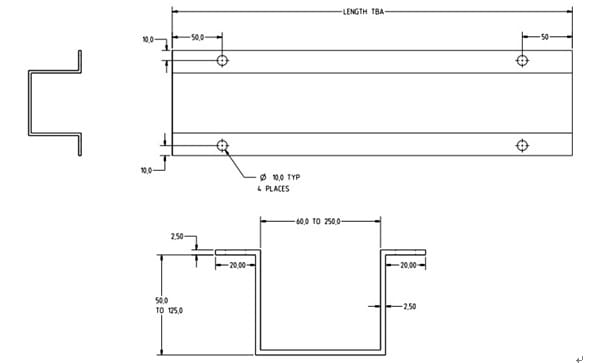

Drawing profile

Reference pictures

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line