Ceiling Panel Machine

Metal Ceiling Plate Roll Forming Machine

Metal Ceiling Plate Roll Forming Machineis designed for making the ceiling plate production in batch fully automatically. Metal Ceiling Plate Roll Forming Machinedrawing profile for your reference:Finished product profile:Based on the customer requirements and our experience, we design the Metal Ceiling Plate Roll Forming Machinelike following picture:Work Flow of Metal Ceiling Plate Roll Forming Machine Decoiler→Feeding Guide Device→Hydraulic Pre-Punching Device→Rolling Forming System→Hydraulic Post Cutting→Exit RackThe Metal Ceiling Plate Roll Forming Machine is composed by the following elements:1.Manual DecoilerManual decoiler controls the steel coil inner bore shrinkage and stop, t...

Metal Ceiling Plate Roll Forming Machine is designed for making the ceiling plate production in batch fully automatically.

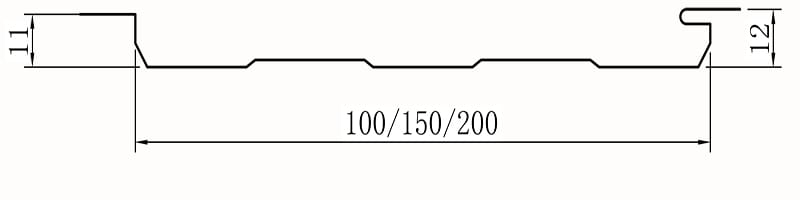

Metal Ceiling Plate Roll Forming Machine drawing profile for your reference:

Finished product profile:

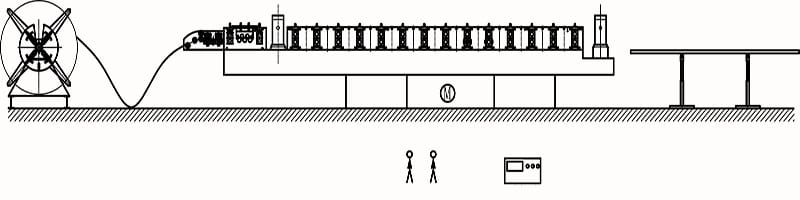

Based on the customer requirements and our experience, we design the Metal Ceiling Plate Roll Forming Machine like following picture:

Work Flow of Metal Ceiling Plate Roll Forming Machine

Decoiler→Feeding Guide Device→Hydraulic Pre-Punching Device→Rolling Forming System→Hydraulic Post Cutting→Exit Rack

The Metal Ceiling Plate Roll Forming Machine is composed by the following elements:

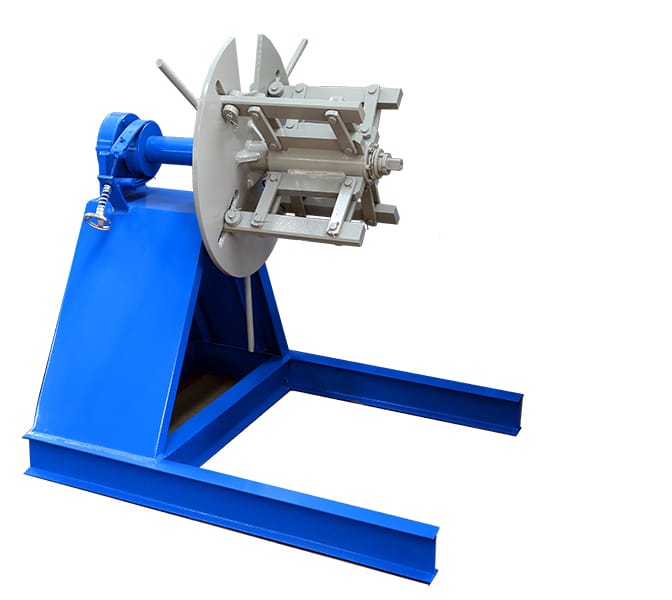

1.Manual Decoiler

Manual decoiler controls the steel coil inner bore shrinkage and stop, the Max feeding width is 30Omm,the Coil ID Range is 508±30mm,the Max capacity is3 ton.

2.Feeding & Hydraulic Pre-Punching Device

With feeding material guide, body frame made from H400 type steel by welding,Pre-punching and post-cutting, use the same hydraulic system.The Hydraulic motor is 4KW,Hydraulic pressure range Is 16Mpa.The Punching and Cutting tool material is mold steel Cr12MoV.

3.Main Machine

The Body frame is made from H400 type steel by welding, the Side wall thickness is Q235 t18mm

The Rollers is manufactured from 45# steel,with Heat Treatment and hard Chrome Coated with thickness 0.04mm,the Main Motor is 5.5KW.

4.Post Hydraulic Cutting Device

The cutting device is Post to cut, stop to cutting, use Three pieces type of cutting blade design and no blanking.The Hydraulic motor is 4KW, The Cutting pressure is0-16Mpa and the Cutting tool material is Cr12MoV.

5. PLC operation system:

The PLC is Control The Quantity And Cutting Length Automatically.

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line