Ceiling Panel Machine

High Speed Ceiling Roll Forming Machine

High Speed Ceiling Roll Forming MachineThe High Speed Ceiling Roll Forming Machine is designed for making the metal ceiling panel production in batch fully automatically.The ceiling paneldrawing profile for your reference:The work flow of the High Speed Ceiling Roll Forming MachineDecoiler→Feeding Guide Device→Rolling FormingSystem→Hydraulic Post Flying Cutting Device→Exit RackBased on the customer requirements and our experience, we design the High speed CeilingRoll Forming Machine like following picture:The high speed ceiling Roll Forming Machine is composed by the following elements:1)Manual Decoiler: one setUn-powered,Manually control steel coil inner bore shrinkage and stop,MaxFeedi...

High Speed Ceiling Roll Forming Machine

The High Speed Ceiling Roll Forming Machine is designed for making the metal ceiling panel production in batch fully automatically.

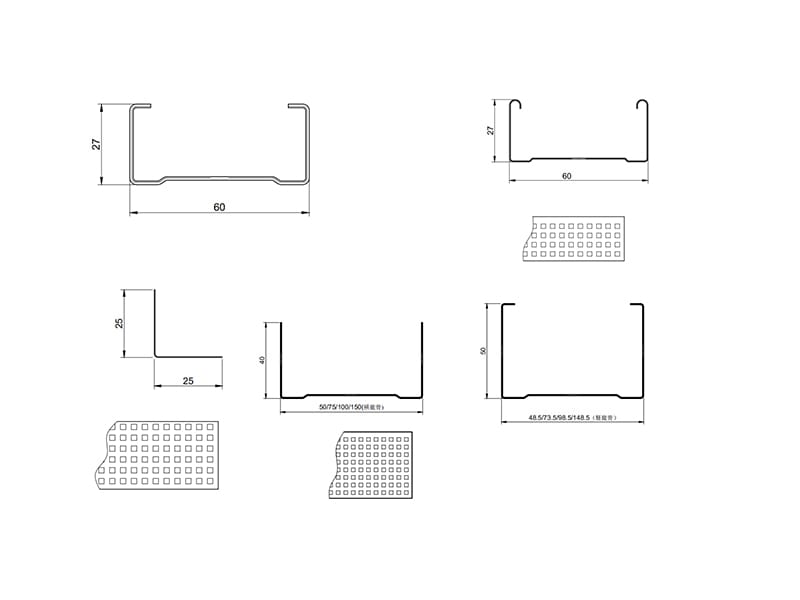

The ceiling panel drawing profile for your reference:

The work flow of the High Speed Ceiling Roll Forming Machine

Decoiler→Feeding Guide Device→Rolling Forming

System→Hydraulic Post Flying Cutting Device→Exit Rack

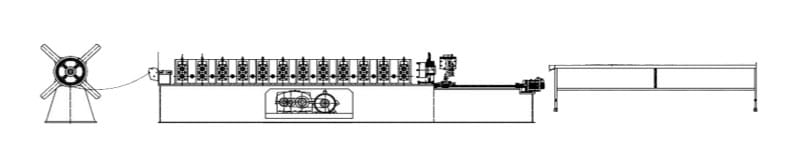

Based on the customer requirements and our experience, we design the High speed Ceiling Roll Forming Machine like following picture:

The high speed ceiling Roll Forming Machine is composed by the following elements:

1)Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop,MaxFeeding width: 300mm,coil lD range 508mm±30mm Capacity: Max.3 Ton

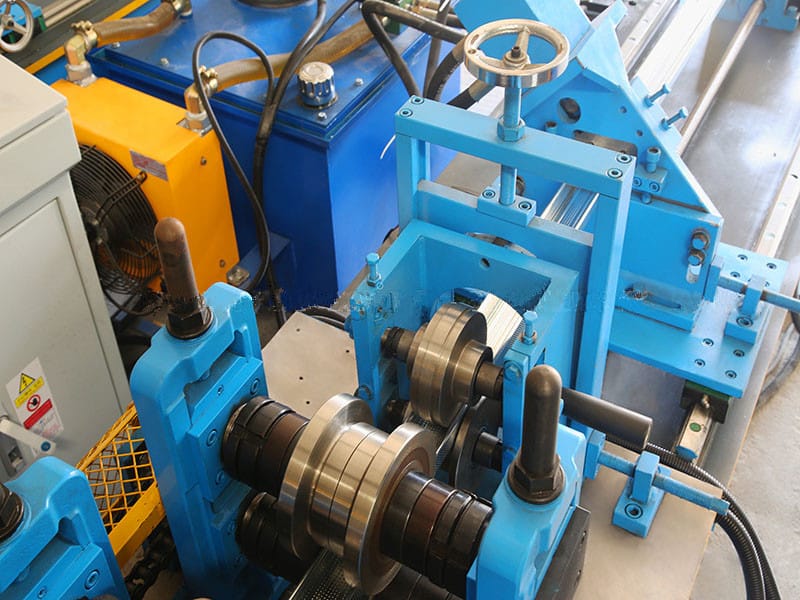

2)Main Machine

With feeding material guide,Body frame made from H400 Steel platewelding.

Memorial arch thickness: Q235 t18mm

Rollers manufactured from Cr12 Steel,CNC lathes,Heat Treatment HRC58-62

The manufactured from 40cr steel,Diameter=dp50mm,quenching and tempering treatment.

Gear & Sprocket driving,about 10-steps to form

Main Motor(Polaroid brand)=5.5KW,Frequency speed control

All the screw bolts with grade 8.8(cheap factories use low grade 4.8)to ensure fix the machine structure tightly and long life during themachine long time running.

Real forming speed:35-40m/min

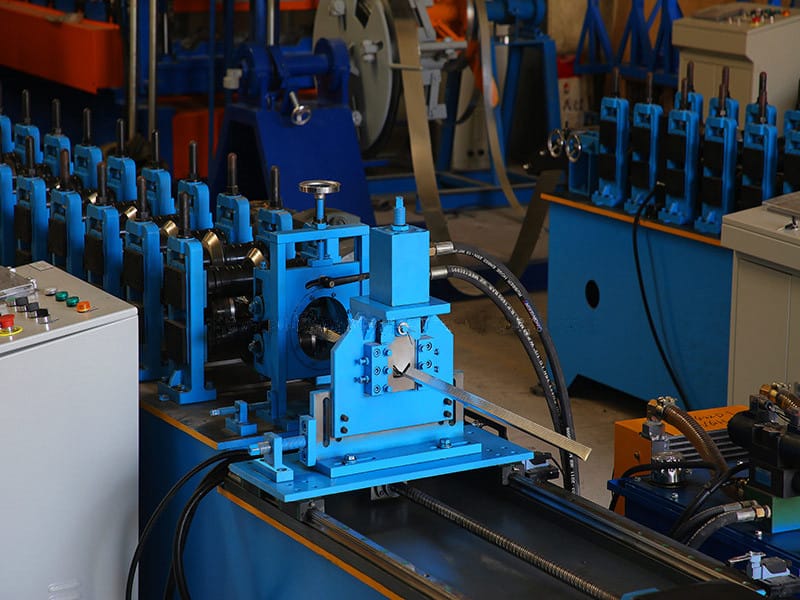

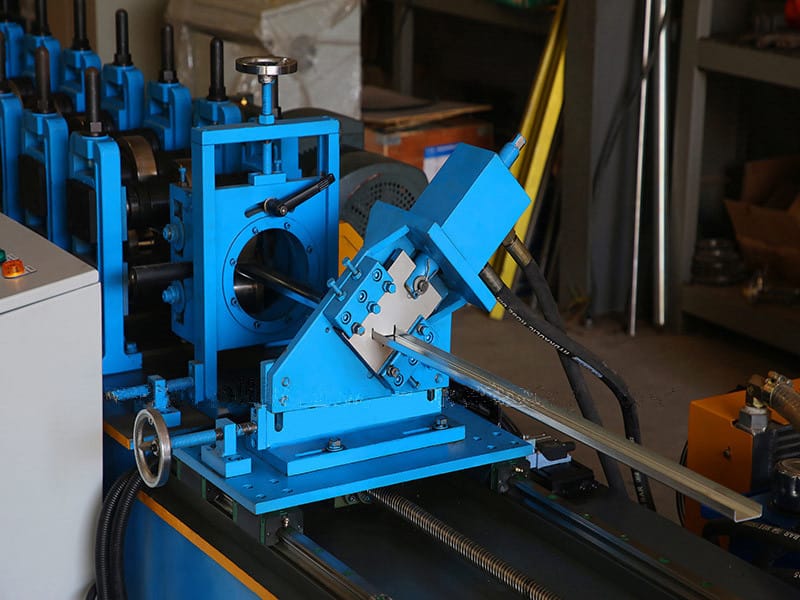

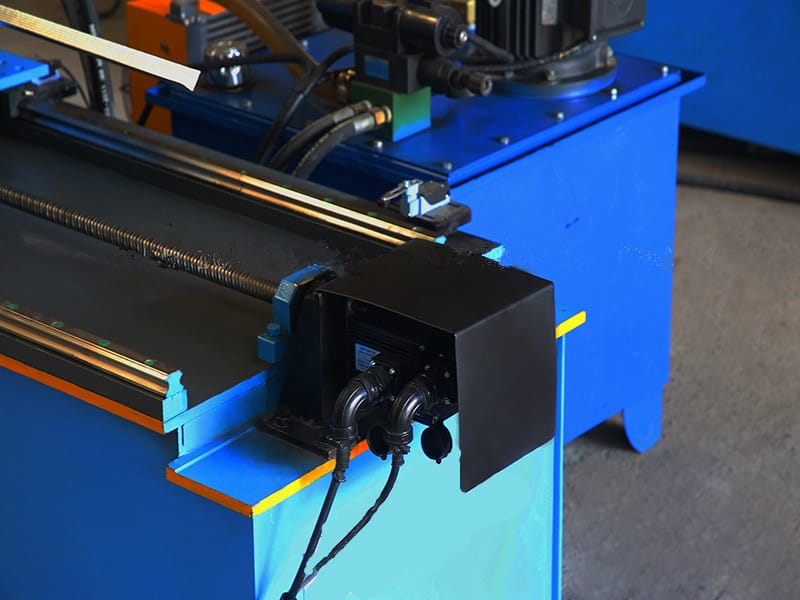

3)Post Hydraulic Flying cutting Device

Not stop to cutting,Two pieces type of cutting blade design, no blankingHydraulic motor:4KW ;Cutting pressure:0-16Mpa,Hydraulic oil number:ShellTellus S2 M 46 or equal model

Cutting tool material:Cr12MoV(=SKD11 with at least one million times ofcutting life), Heat treatment to HRC58-62 degree

The cutting power is provided by the main engine Independent hydraulicstation

The lndependent hydraulic system with oil filter for the oil filtration,to ensure the circulated oil is clean and lengthen the life of hydraulic system

![]()

With servo motor will make the cutting and product speed morestable and quick.Servo motor power:1.5Kw

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line