Cable Tray Machine

Ladder type Cable Tray Forming Making Machine

Ladder type Cable Tray Forming Making Machine TheCharacter of Cable Tray forming making machien ‘s main Structurea) It is very easy to install the equipment and suitable for producing in the factory.b) Low noise with high efficiency.c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.d)The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.1.Technical Parameter of ladder type cable tray forming making machineItemsSpecificationsWidth of the profile100mm/150mmHeig...

Ladder type Cable Tray Forming Making Machine

The Character of Cable Tray forming making machien ‘s main Structure

a) It is very easy to install the equipment and suitable for producing in the factory.

b) Low noise with high efficiency.

c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

d) The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

1.Technical Parameter of ladder type cable tray forming making machine

Items | Specifications | |

Width of the profile | 100mm/150mm | |

Height of the profile | 20mm | |

Thickness | 1.5-2mm | |

Un Coiler | 3 ton passive | |

Forming system | Rolling Speed | 10-12m/min without punching 5-6 meters with punching |

Roller Stations | About 12 stations | |

Roller Material | Gcr 15with quenching

| |

Shaft | Dia 75mm | |

Maim Motor Power | 7.5kw | |

Hydraulic cutting Power | 4 kw | |

Cutting system | Material Of Cutting | CR12 with quench treatment |

Hardness | HRC58-62 | |

Tolerance | +-1.5mm | |

Electrical control system | Electric Source | 220V, 60HZ,3 phase Also can satisfy Customer’s require |

Control System | PLC (Panasonic) as list in the note | |

Weight | About 15 tons | |

Profile adjustment | By spacers manually | |

Way Of Drive | 1.5 inches chain | |

Size of machine | Length 7500mm* Width 700mm* Height 1000mm |

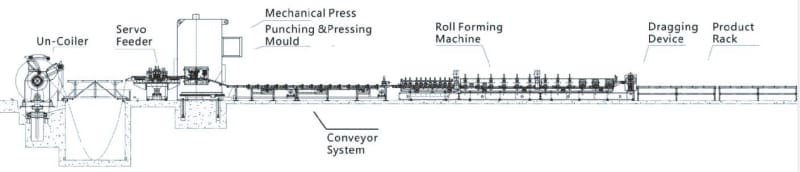

2. The flow chart of the ladder type cable tray forming making machine

Decoiler- feeding with guide --Punching--Roll forming-Cutting-Out tables

3.Machine Components of ladder type cable tray forming making machine

Name | Qty |

5 tons hydraulic decoiler | 1 set |

Roller Leveller | 1 set |

Servo feeding machine | 1 set |

Punching Press machine | 1 set |

Punching moulds | 4 sets |

Roll forming machine | 1 set |

PLC | 1 set |

Cutting device | 1 set |

Out put table | 2 sets |

Hydraulic station | 1 set |

Toolbox | 1 set |

Spare Parts | 1 set |

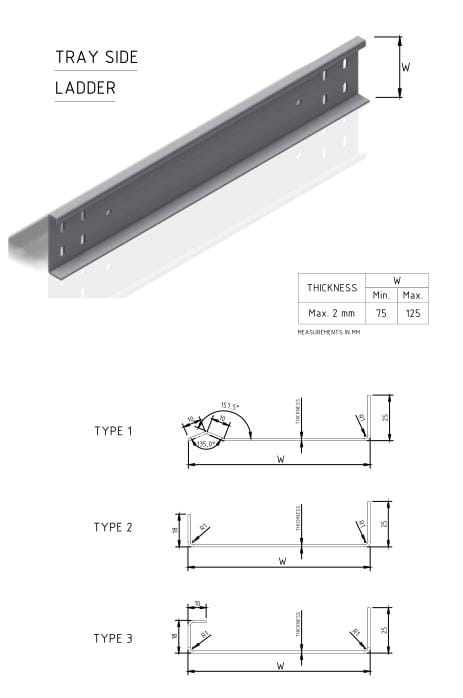

4.Profile drawing

To make the 3 profiles by changing rolls

5.Details of each compositions

De-coiler

Powered single header

Type 3 Tonne passive

Capacity 3000KG

Cutting way

(1) Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

(2) Material of blade: CR12 with heat treatment

(3) Length measuring: Automatically

(4) Tolerance of length: + 1.5mm

Out Tables

Length : 1.5m

Quantity: 2 units

Control Box: PLC Panasonic Brand

(1) Power supplier: 380 V, 50 Hz, 3Phase (adjusted with the requestment)

(2) Length & quantity measurement automatically;

(3) Length & quantity controlled by PLC,

(4) Length inaccuracy can be amended easily.

(5). Control panel: Button-type switch and touch screen

(6) The language in the touch screen: English and Chinese

(7) Unit of length: millimeter (switched on the control panel)

More pictures of the cable tray roll forming line

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line