C & Z Purline Machine

C channel steel stud roll forming machine

C channel steel stud roll forming machineC channel steel stud roll forming machineis weldly used in the celling and drywall construction. Compared with cement construction and wooden construction,Steel frame is more light and durable.The Finished productThe application picture:The drawing profiles as following you can chooseAdvantages of C channel steel stud roll forming machine1. One machine can producedifferent sizes as reuqest2. High automatic3.Speed is optional:20m/min,30m/min,60m/min,80m/min4.User can set production quantity, production speed on control cabinet.Component of C channel steel stud roll forming machine:ItemNameQuantityRemark1Manual decoiler11.5T capacity2Main roll former1Do...

C channel steel stud roll forming machine

C channel steel stud roll forming machine is weldly used in the celling and drywall construction. Compared with cement construction and wooden construction,

Steel frame is more light and durable.

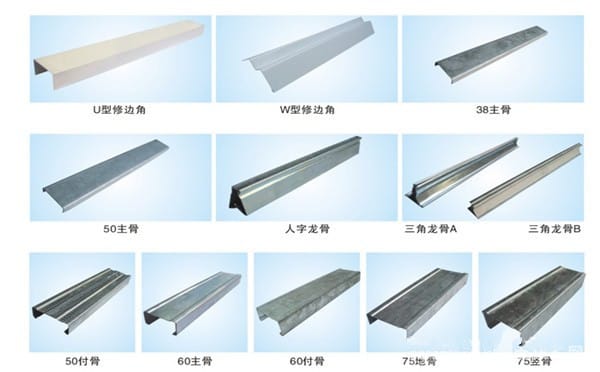

The Finished product

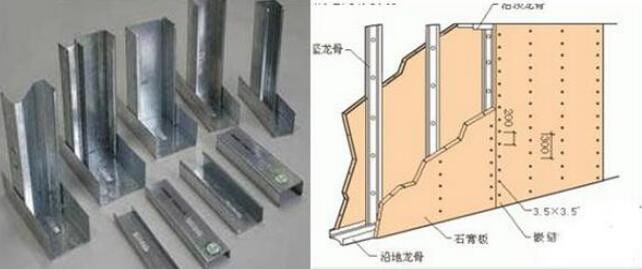

The application picture:

The drawing profiles as following you can choose

Advantages of C channel steel stud roll forming machine

1. One machine can produce different sizes as reuqest

2. High automatic

3.Speed is optional:20m/min,30m/min,60m/min,80m/min

4.User can set production quantity, production speed on control cabinet.

Component of C channel steel stud roll forming machine:

Item | Name | Quantity | Remark |

1 | Manual decoiler | 1 | 1.5T capacity |

2 | Main roll former | 1 | Double sets |

3 | Control system | 1 | Full automatic |

4 | Hydraulic system | 1 | Famous brand |

5 | Run-out table | 1 | 3m |

Working process of the C channel steel stud roll forming machine

Decoiler--feeding--roll forming--punching(if need holes or logo)--cutting--product table

Technical parameters for the whole production line:

1.Manual decoiler

Name | Description |

Capacity | 1.5T |

Coil inner diameter | 450-550mm |

Coil width | 300mm(as profile drawing) |

2.Roll forming machine

Name | Description |

Machine structure | cast iron roller fixer |

Main power | 5.5KW |

Forming stations | 11 stations |

Way of drive | by Chain |

Diameter of shaft | 50mm |

Speed | Speed is optional from 20m/min-80m/min |

Material of roller | CR12 with quenched treatment |

Material of shaft | 45# steel |

Material of blade mould | Cr12, quenched 58-62 |

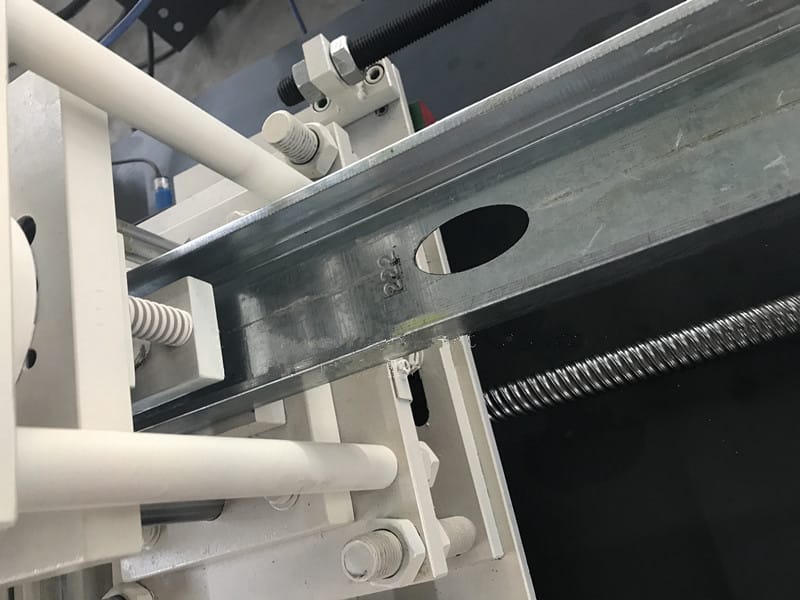

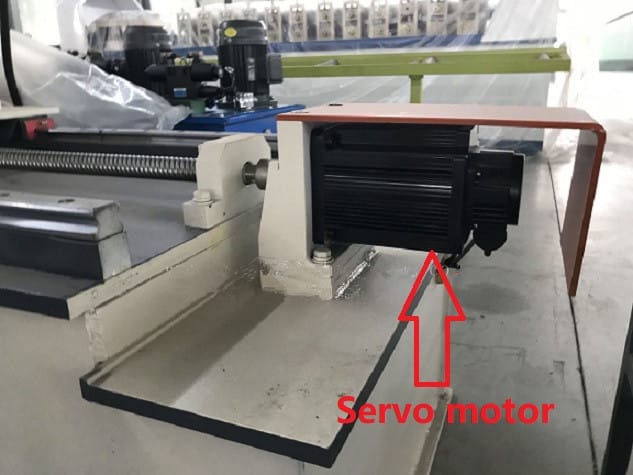

Way of cutting | Hydraulic mould cutting(flying cut,cut without stop) with SERVO MOTOR DRIVED |

Length tolerance | +/-1.0mm |

Voltage | 380V,50Hz,3P |

3.Control system

Name | Description |

Control system | PLC |

Screen type | Touch screen |

Screen brand | Delta or Siemens |

Inverter brand | Delta or Siemens |

Encoder | Omron |

Eletronic component | Schneider |

Function | Control the product length,quantity and batch |

4.Hydraulic system:

Name | Description |

Hydraulic pressure | 16Mpa |

Hydraulic power | 4kw |

Cooling system | fan cooling |

5.Product table

Name | Description |

Length | 3 meters |

Type | Manual or Pneumatic |

Structure | Square pipe welded |

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line