Shutter Door Machine

Zhongtuo rolling shutter door track door rail roll forming machine

Zhongtuo rolling shutter door track door rail roll forming machineZhongtuo rolling shutter door track door rail roll forming machine is designed to produce the shutter door rails in batch fully automatically. For the door track and door rails, in the market, there are many types, here I will introduce one special one with the anti-noise function.Rolling shutter door track or guide rails areusually made out of galvanizedsteel or coldrolled steel strips with thickness 1.2-2mm andwhenever there is a roller shutter door or asliding door installed, there will be the doortrack or guide rails.Different with other U rails, it can remove the noise when working.If you need, those types, Zhongtuo rolli...

Zhongtuo rolling shutter door track door rail roll forming machine

Zhongtuo rolling shutter door track door rail roll forming machine is designed to produce the shutter door rails in batch fully automatically. For the door track and door rails, in the market, there are many types, here I will introduce one special one with the anti-noise function.

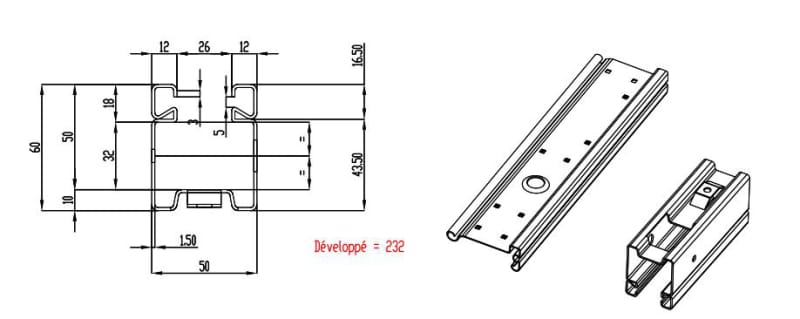

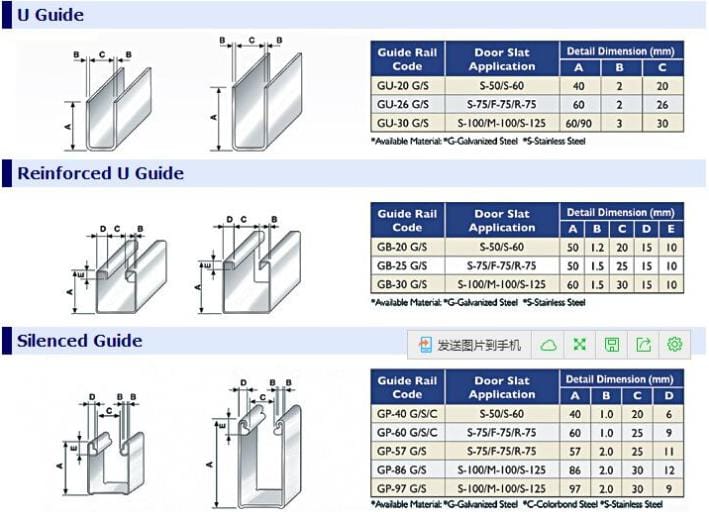

Rolling shutter door track or guide rails are usually made out of galvanized steel or cold rolled steel strips with thickness 1.2-2mm and whenever there is a roller shutter door or a sliding door installed, there will be the door track or guide rails.

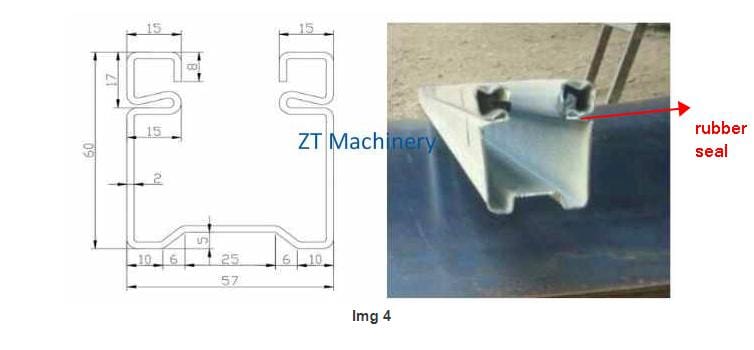

Different with other U rails, it can remove the noise when working.

If you need, those types, Zhongtuo rolling machinery also can make such type for you.Zhongtuo rolling shutter door track door rail roll forming machine design:

The rubber seal could be made online no need the workers to fill offline. Here are some details about how the seals are filled:

Here are some parameters of Zhongtuo rolling shutter door track door rail roll forming machine for your reference:

Uncoiler: Manual Uncoiler

Loading Weight: 3T

Inner Diameter: 480-520mm

Outer Diameter: Max 1250mm

Leveler: with a Feeding Guide Unit

7-Roller Leveler: 3 rollers up and 4 rollers down with no power

Leveling Thickness: 2mm maximum

Diameter of Leveling Roller: 76mm

Main Structure of the Machine: 36# “H” Beam Steel

Rolling Stations: 24 stations

Forming Speed: Approx. 8-12m/min

Diameter of Shaft: 65mm

aterial of Shaft: 45# steel with heat treatment

Material of Roller: Gcr15 Bearing Steel

Transmission: Chains-bracket

Main Motor Power: 11KW (subjected to final design)

Cutting: Hydraulic cutting

Cutting Length and Quantity: Clients can set the required length and quantity on the PLC touch screen

Electrical Motor Power: 3KW (subjected to final design)

Tolerance of Cutting Length: +/-2mm

PLC Control Box: 700mmx1000mmx300mm

Computer Control System: Panasonic PLC

Encoder: Omron Brand

Voltage: customize.

Usage of rolling shutter door track door rail:

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line