Door Frame Machine

Metal Frame Doors Roll Forming Machine

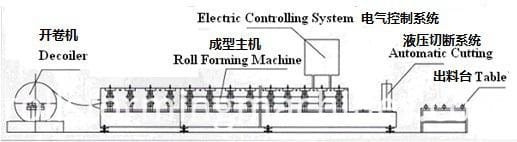

Metal Frame DoorsRoll Forming Machine:Metal Frame Doors Roll Forming Machine is design to roll cold galvanized steel with thickness from 0.4mm to 1.5 mm. steel & metal door frame machine can produce twotypes of frame, one is use for shutter door, the shape likes U or similar, another one is used for door panel.Metal Frame Doors Roll Forming Machineconsists of decoile,-Feeding and Leveler, roll forming ,cutting part, runout table, PLC control box and hydraulic station.The production Process:De-coiler----Feeding and Leveler---Roll Forming---Cutting Part---Runout TableComposition of SteelDoor Frame Roll Forming Machine:1. De-coilerLoading capacity:1.5TUncoiling width:300mm (according to the pro...

Metal Frame Doors Roll Forming Machine:

Metal Frame Doors Roll Forming Machine is design to roll cold galvanized steel with thickness from 0.4mm to 1.5 mm. steel & metal door frame machine can produce two

types of frame, one is use for shutter door, the shape likes U or similar, another one is used for door panel.

Metal Frame Doors Roll Forming Machineconsists of decoile,-Feeding and Leveler, roll forming ,cutting part, runout table, PLC control box and hydraulic station.

The production Process:

De-coiler----Feeding and Leveler---Roll Forming---Cutting Part---Runout Table

Composition of Steel Door Frame Roll Forming Machine:

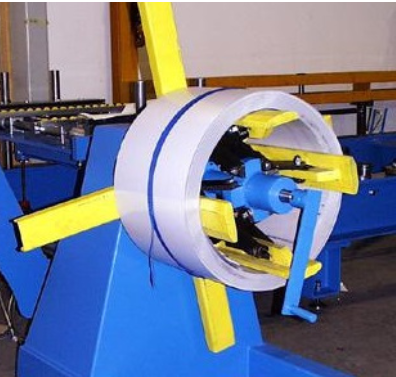

1. De-coiler

Loading capacity:1.5T

Uncoiling width:300mm (according to the profile drawing)

Inner diameter450-550mm

2. Feeding and Leveler

Usage: Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

3. Roll Forming

Roller material :45# steel, surface hard chromium plating.

Shaft material : 45# steel with tempering

Outer diameter of shaft :70mm

frame : 400H steel

Voltage: 380v,50Hz,3 phase As customer`s need

Dimensions:15400 * 1800 *1800mm Final size depend on the design

Main power: 8.5-15kw Depend on the thickness of material and size of machine

Forming steps rollers: 12-20 stations Final rollers depend on the design

Speed :8-15m/min

4.Cutting Part

Material of blades : Gcr12MoV quenched

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line